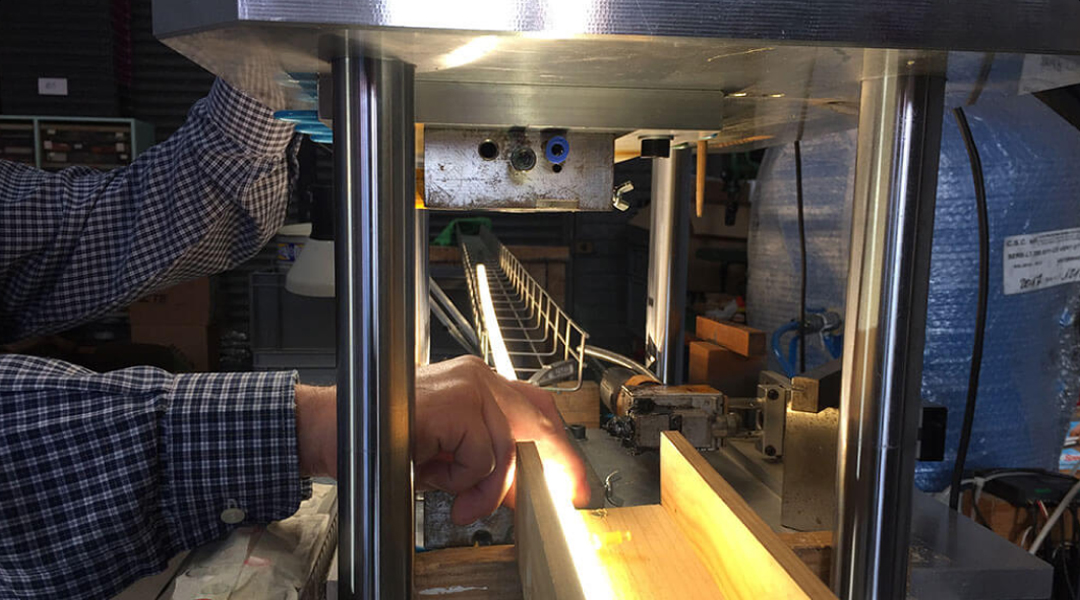

At the center of the manufacturing process is the crucial step of injection molding: this consists of forcing or injecting molten plastics into a steel or aluminum mold, where they are cooled and take the shape of empty space. The Precision Group knows the art and science of injection molding well, with a highly trained and specialized team working around the clock to fulfill customer orders on numerous injection presses, including the Toshiba All-Electric press. 390 ton with a Yushin Robot (see kit for full list). The end result of our work is high-quality plastic components that precisely meet the requirements of our customers.

What sets us apart and make us impenetrable? Put your project in the hands of the experts.

High quality Assurance

Customized Solutions

Specialized Machines

At Precision Group our mission is simple: Every moment of our process is an opportunity to demonstrate our commitment to quality while, at the same time, guaranteeing customer satisfaction.

The Precision Group offers a range of specialized services within its injection molding division, including overmolding, insert molding, hot oil molding, and master unit die casting (MUD).